EN253 SCH40 Underground Polyurethane Foam Insulated Steel Pipe Prefabricated HDPE Jacket API Standard Cutting Welding Included

DZD 23,368.11

Description

Technical Composition

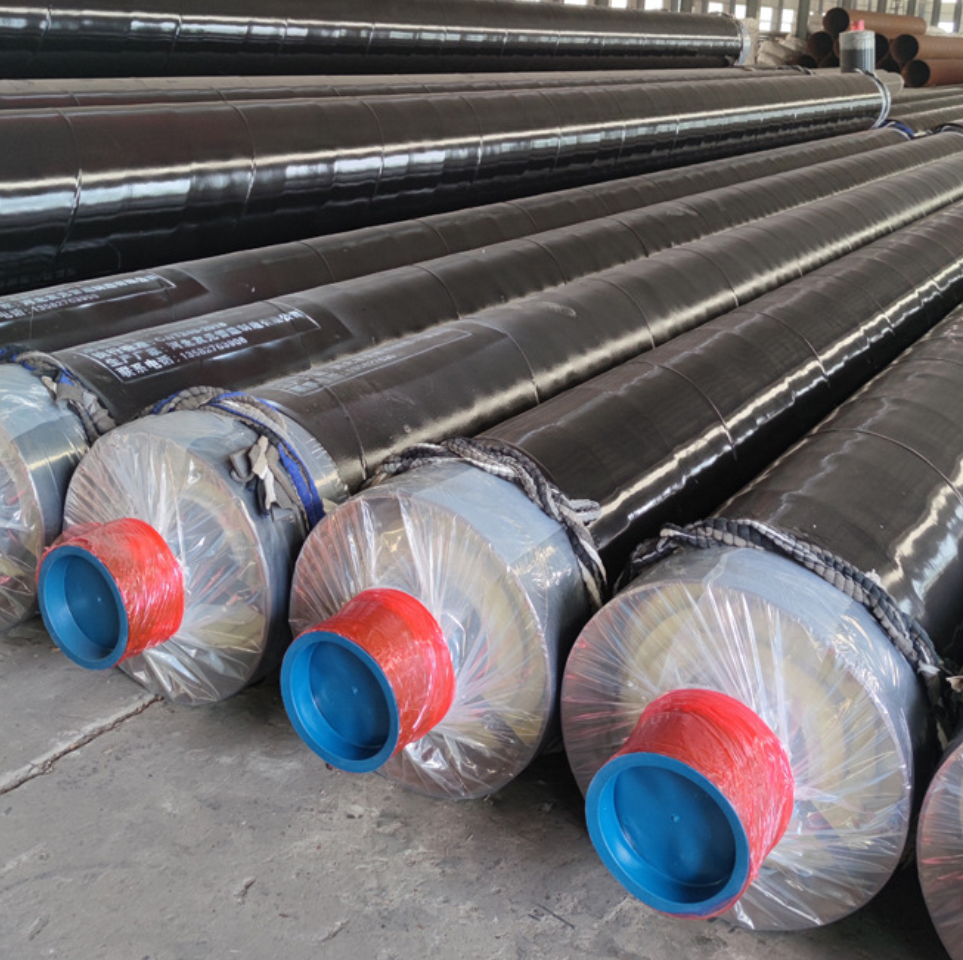

The system utilizes a triple-layer construction designed to act as a single functional unit, often referred to as a "sandwich" or "trinity" structure:

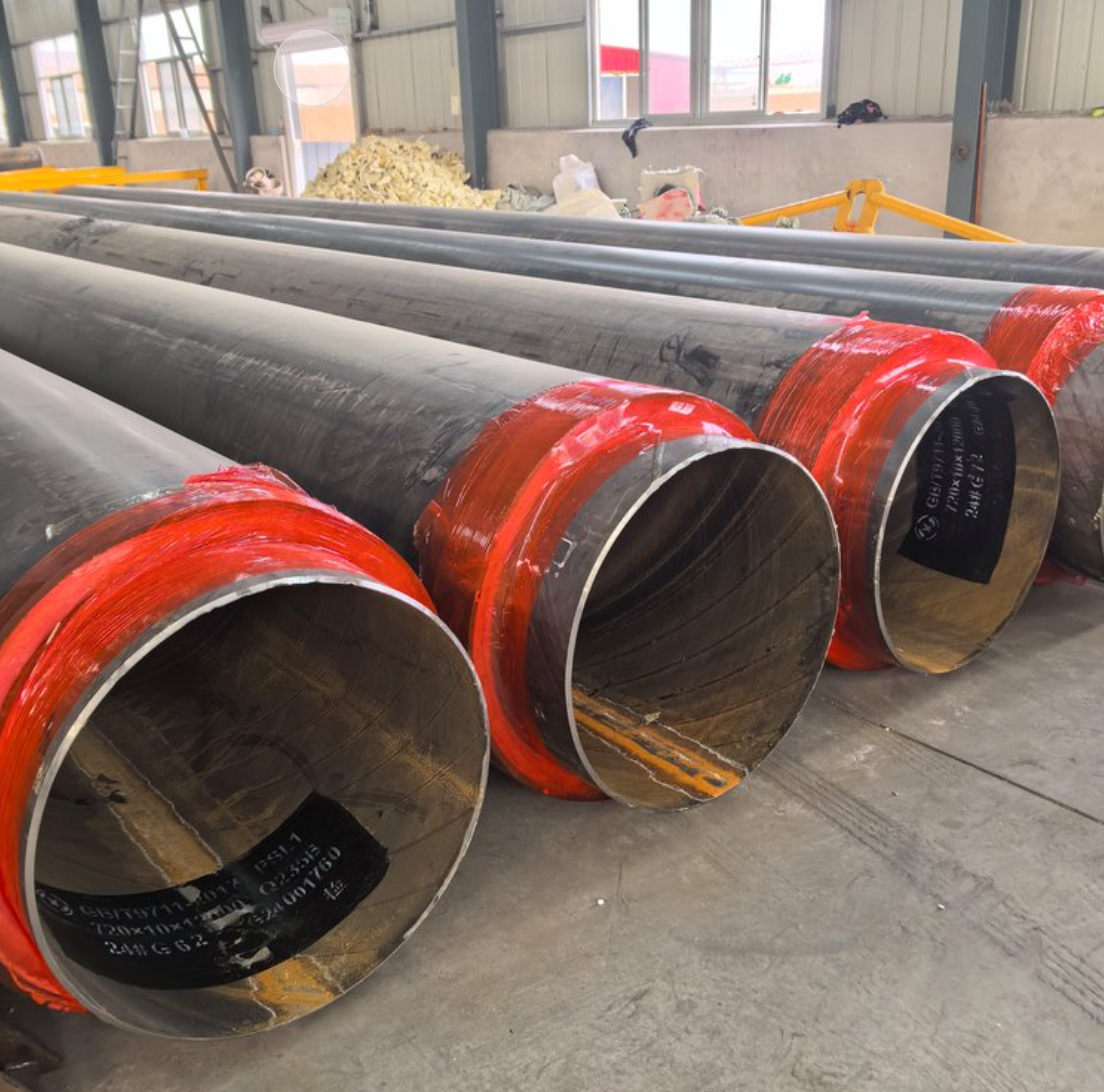

Inner Working Pipe: Typically constructed from 20# Steel or Q235B, providing high structural integrity for high-pressure thermal applications.

Insulation Layer: Rigid polyurethane (PUR) foam. This layer is bonded to both the inner and outer pipes, ensuring no air gaps exist that could lead to heat loss or internal corrosion.

Outer Protection: High-density polyethylene (HDPE) guard pipe. This provides the primary defense against moisture, soil acidity, and mechanical stress.

Performance Characteristics

Thermal Efficiency and Energy Savings

The system is engineered for maximum energy retention during fluid transport.

Thermal Conductivity: The rigid polyurethane foam provides a low thermal conductivity of 0.033 W/(m·K).

Energy Conservation: This high-efficiency insulation significantly reduces heat dissipation compared to traditional lagging methods, allowing for longer transmission distances with minimal temperature drops.

Durability and Resistance

Corrosion Resistance: The HDPE outer jacket is chemically inert, preventing the steel carrier pipe from coming into contact with groundwater or corrosive soil elements.

Waterproofing: The closed-cell structure of the PUR foam, combined with the seamless HDPE shell, creates a moisture-proof barrier that maintains its integrity even when installed in high-water-table areas or directly in water.

Economic Advantages

Implementing this prefabricated system offers a measurable reduction in the Total Cost of Ownership (TCO).

Engineering Cost Reduction: According to industry data, dual-controlled heating pipelines can reduce overall construction and engineering costs by 10% to 25%.

Installation Speed: Because the pipe is prefabricated in a factory environment, on-site work is limited to jointing, which significantly shortens construction timelines and reduces labor costs.

Service Life: The system is designed for a long service life, reducing the frequency of replacement and the costs associated with pipeline maintenance and emergency repairs.

Feature,Detail

Size Range,DN250 – DN350

Standard Length,5.8m – 12m (Customizable)

Materials,"20# Steel, Q235B, Polyethylene, Polyurethane"

Certifications,"ISO9001, ISO14001, ISO45001, GB/T series"

Primary Use,"District heating, district cooling, and community secondary networks"

Spécifications Techniques et Commerciales

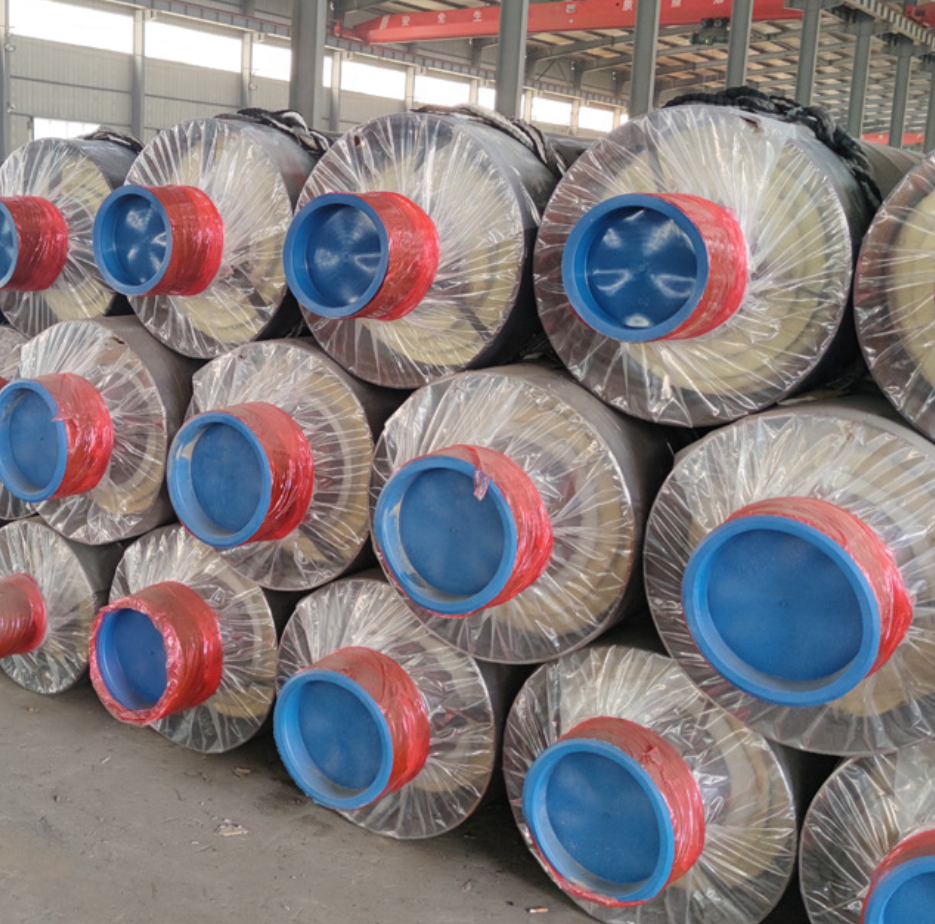

Logistique et Emballage

Shipping fee and delivery date to be negotiated. Chat with supplier now for more details.

World

Wood Box

Informations sur le Vendeur